|

Up

Up

The Real McCoy

The Real McCoy

(You are here.)

Need

to Need

to

find your

bearings?

Try

these

navigation aids:

If

this is your first

visit, please stop by:

Something

to share?

Please:

|

|

Available in Française, Español, Português, Deutsch, Россию,

中文,

日本, and others.

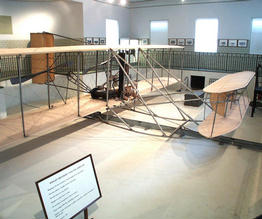

n

preparation for building a flying copy of the 1905 Wright Flyer III, we took a trip to

the Wright Brothers Aviation Center at Carillon Historic Park in Dayton, Ohio to

inspect the real McCoy -- the original 1905 aircraft, restored. The aircraft is displayed in a specially designed

building, Wright Hall. As you walk in, it's slightly

below you in a huge well or "pit." The curatorial staff, Mary Mathews

and Jean Palarmo, kindly let us into the pit to take close-up photos. This was no small favor,

since this aircraft has been dubbed a national treasure by an act of Congress.

It's also the only aircraft to be designated as a National Historic

Landmark. It is indeed a treasure. Charles Gibbs-Smith, a prominent aviation historian, dubbed this restored airplane

the most valuable aviation artifact anywhere because it was the

first practical airplane, capable of taking off

under its own power, navigating to a pre-determined location, and -- as

Wilbur Wright so succinctly put it -- "landing without wrecking." n

preparation for building a flying copy of the 1905 Wright Flyer III, we took a trip to

the Wright Brothers Aviation Center at Carillon Historic Park in Dayton, Ohio to

inspect the real McCoy -- the original 1905 aircraft, restored. The aircraft is displayed in a specially designed

building, Wright Hall. As you walk in, it's slightly

below you in a huge well or "pit." The curatorial staff, Mary Mathews

and Jean Palarmo, kindly let us into the pit to take close-up photos. This was no small favor,

since this aircraft has been dubbed a national treasure by an act of Congress.

It's also the only aircraft to be designated as a National Historic

Landmark. It is indeed a treasure. Charles Gibbs-Smith, a prominent aviation historian, dubbed this restored airplane

the most valuable aviation artifact anywhere because it was the

first practical airplane, capable of taking off

under its own power, navigating to a pre-determined location, and -- as

Wilbur Wright so succinctly put it -- "landing without wrecking."

This treasure was almost lost to us. The Wrights last flew it in

1908 at Kitty Hawk making the world's first

passenger flights. But Wilbur had difficulty with the

unfamiliar controls and wrecked the airplane, so the Wrights

abandoned it in their shed. It remained there until 1914 when Zenas

Crane obtained Orville's permission to salvage it for the Berkshire

Museum in Pittsfield, MS. The Berkshire Museum, however, never

touched the wreck and it remained in storage until 1946 when Edward

Deeds began building Carillon Historic Park. Deeds asked Orville for

an airplane; Orville asked the Berkshire Museum to return the Flyer.

Harvey P. Geyer, who had once worked for the Wright Company and

himself an accomplished inventor, headed the restoration under

the supervision of Orville Wright. Louis P. Christman worked with Orville on the

engineering drawings.

The restored aircraft was unveiled in 1950. It had been "lying

in state" for half a century when we were allowed into the pit. For us, this was

a marvelous opportunity to get nose to

nose with the craftsmanship of the Wright brothers, marvel at their attention to

detail, and explore their innovative, no-nonsense approach to engineering. We

thought you might like to the share this adventure, so here, with many thanks to

Carillon Historic Park, is a photographic walk-around of the

original 1905 Wright Flyer III.

|

Let's begin with a walk around the "Pit" in Wright

Hall, where the 1905 Flyer III is displayed. This is

the scene that greets you as you enter from the east.

|

Move to your right and follow the walkway that runs

around the pit.

The Flyer rests on a section of the launch rail.

|

The most distinctive feature of this airplane is the prominent forward

elevator or "canard" out ahead of the wings. This is almost as large

as the the Wrights' first man-carrying glider.

|

Here's the Flyer as it appears head-on. At the back of the hall, you

can see the bronze busts of Wilbur and Orville Wright.

|

Continuing around, here's a diagonal view from the

front left. The large green wooden box in front of the left wing is

the Wrights' tool chest. They kept this at Huffman Prairie when they

were developing the Flyer, and it may have also traveled with them

to and from Kitty Hawk.

|

A little further on, here's an overview of the Flyer from the back

left. You get a real sense of just how big this aircraft is -- 40

feet from wing tip to wing tip and 27 feet from nose to tail.

|

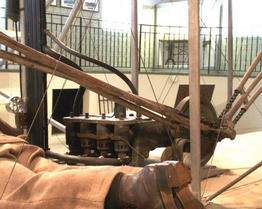

A close-up view of the Flyer's cockpit from behind and to the left.

The Flyer III was the last Wright aircraft on which the brothers lay

prone to fly it. Note that the tubes that enclose the drive chain on

the left side are crossed. The propellers rotate in opposite

directions.

|

Another view of the chain tubes at the rear of the

Flyer. The Wright made the propellers contra-rotate so the

centrifugal and coriolis forces generated by the props would cancel

each other out and not pull the aircraft to one side.

|

As we walk down the stairs that lead from the walkway into the pit,

our perspective changes. Now the aircraft isn't just big; it's over

8 feet tall.

|

Looking down the length of the wing from the left. This what the

brothers or their mechanic Charley Taylor must have seen running

along at the wing tip as the Flyer launched.

|

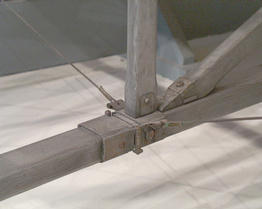

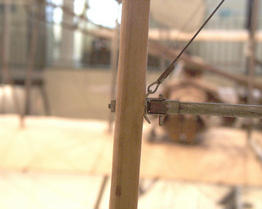

A view of a strut fitting, joining the lower wing to

a vertical strut. These were in fact hinges that allowed the wings

to move when the pilot warped them.

|

Closer still to the strut fitting. Note how the Wrights "safety wired"

the flitting so the strut and the rigging would not slip off.

|

Most of these fitting are simply screwed to the wing

spars. A very few are attached with bolts that go through the spars. |

The wing covering is applied on the "bias" -- the

threads run diagonally across the ribs. Each thread becomes a tiny

brace, greatly increasing the strength of the wings.. |

The post and braces that attach the skids to the

Flyer are fitted and screwed to the wings. |

The skids themselves are split at the front of the aircraft, then

joined with this U-shaped fitting. This allowed the Wrights to

easily detach the front skid assemblies when they stored the Flyer.

|

Beneath the wings, the skids rest on a wheeled

carriage or "truck." This truck carries the aircraft as it rolls

down the launch rail, but is left behind when the Flyer takes off..

|

A closer view of the wheeled truck and the launch rail.

|

Just in front of the wings, a brace runs from the

leading edge of the lower wing and joins the skid just as it begins

to curve upwards.

|

.

Following the curved portion of the skid forward, another diagonal

brace joins it midway. Just forward of this brace, a horizontal tie

bar joins the left and right skids.

|

This tie bar mounts a roller that rides the rail

during a launch, keeping the Flyer pointed forward. This roller is

actually an old bicycle wheel hub.

|

Horizontal "outriggers" run from the leading edge of the wing to

vertical posts that support the elevator. Where an outrigger crosses

a brace, the two parts are bolted together,

|

The bottom portion of the elevator support post is curved and fitted

to the skid. Another diagonal brace, running from the leading edge

of the top wing, joins the skid and the post.

|

Another view of the juncture between the skid, front brace, and

elevator support post. A small horizontal tie bar joints the posts.

|

A view of the elevator and the mechanism that adjusts the angle of

the top and bottom control surfaces. The semi-circular air foils,

called "blinkers" by the Wright brothers, help to stabilize the

Flyer in a turn.

|

The chains and wires lead to the elevator control in the cockpit.

Moving this control rotates the dumbbell-shaped casting and the

horizontal shaft to which it is attached.

|

As the shaft rotates, it cause three horizontal control arms -- one

at each end and one in the middle of the shaft -- to rotate as well.

|

Each end of each control arm is a double pivot that attaches the arm

to to vertical actuators running to the top and bottom control

surfaces.

|

Each actuator arm is attached to a control surface at the leading or

trailing edge with another pivot. As the pilot moves the elevator

control , this motion is transferred through the wires, dumbbell,

shaft, and arms to the control surfaces, changing their angle up or

down.

|

You can't see the hardware because it is covered in cloth, but each

elevator control surface is hinged in the middle. As the surface

moves changes its angle, it also changes camber, curving up or down.

|

Like the biplane wings, the biplane elevator is rigged with wires

running diagonally to create a strong truss. Although the elevator

surfaces can pivot, changing angle and camber, the assembly is rigid

from side to side.

|

The pilot, engine, and drive train occupy four "bays" in the center

of the aircraft. (A bay is a space between two struts.) These four

bays are completely rigid, the wings don't warp in this area.

|

The cockpit bay includes the pilot, manual controls for roll, pitch

and yaw, and a rudimentary set of flight instruments.

|

The engine bay is just to the right of the pilot. The red hot

combustion chambers are just 11 inches from the pilot's right side.

|

The engine has four cylinders, make-and-break ignition (no spark

plugs), and develops 25 horsepower. The small chain in front runs a

camshaft, opening and closing the exhaust valves.

|

The Richard Anemometer attached to the front center strut serves as

a flight recorder, recording the time aloft and distance flown

through the air.

|

Once the aircraft has landed, the pilot pulls on the lever to his

right, stopping the wind vanes and stopwatch incorporated into the

anemometer.

|

That same action (pulling the lever) closes the valve that feeds gas

to the engine, stopping it. The pilot can also push down on a lever

that opens all the exhaust valves. This too will stop the engine by

releasing the compression.

|

Just above the anemometer is the gas tank. The Wrights carried

enough gasoline to fly for a little over half an hour.

|

Near the top of the center strut is the reservoir for the radiator.

There is no radiator cap; the steam is allowed to escape without

building up pressure.

|

Just to the right of the center strut, mounted to the bottom wing,

is the release latch. A cable was hooked to this latch that

restrained the Flyer and kept it from rolling forward.

|

When it was time to take off, the pilot reached down and pulled

forward on the metal latch. The latch arm pivoted backwards, the

cable dropped, and the Flyer began its take-off roll.

|

At the pilot's right is a horizontal lever that controls the rudder

and yaws the Flyer right and left. To his left is a vertical lever

that controls the elevator, pitching the nose up and down.

|

The elevator control lever is mounted to a horizontal shaft which

turns a pulley. The wires from the elevator (mentioned above) are

attached to this pulley.

|

The pilot's hips rest in a hip cradle. This is the roll control. As

the pilot moves his hips right and left, the cradle pulls on wires

that warp the wings.

|

The pilot's legs stretch back under the drive train. The chain drive

stretches out from the engine in two directions to the right and

left propeller drive shafts.

|

The pilot's feet are positioned in a footrest that is attached to

the rear spar.

|

Moving around to the back of the Flyer, this wide angle shot shows

the portion of the wing that warps when the pilot moves the hip

cradle.

|

The strut fitting for the rear strut nearest to the left wingtip.

The wire attached to it is a control wire, not structural rigging.

|

The trailing edge is wire that runs from rib to rib. You can't see

it because it is covered with cloth, but it fits in the notches at

the rib ends. Note the seam that joins wing sections.

|

Just inside the seam is the lower control pulley. The control wires

are separated at this point and joined with a chain.

|

The same is true of the upper control pulley and wires. The Wrights

couldn't run a solid wire over a pulley; it would fatigue and break.

So they used bicycle chain at each pulley.

|

Another view of the footrest. The pilot's toes should be hooked

under the bar and each shoe tight against the side boards. This

provided an anchor for the pilot when he moved his hips right and

left.

|

Just over the pilot's legs, you can see the four combustion chambers

on the left side of the engine. These ran exceedingy hot.

|

Looking forward, note how the pilot had to arch his back and hold

his head up to fly. This created enormous physical strain during

long flights.

|

When the engine of the Flyer III was built in 1904, it produced just

16 horsepower. But the Wrights continued to tweak it until by

September 1905, it was producing 24.

|

The engine ran at about 1300 rpm. The small gears on the crankshaft

and the large gears on the propeller shafts reduced this so the

props turned at just 450 rpm.

|

The note on the wooden mount for the magneto says "Found near Kill

Devil Hills Aug 6 '08. This part and many others were recovered from

souvenir hunters on the Outerbanks.

|

The supporting structure of the drive train consisted of dozens of

metal tubes. As bicycle manufacturers, this was something with which

the Wrights were very familiar.

|

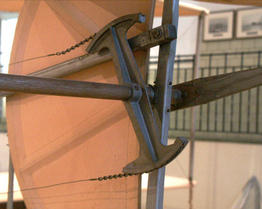

The large gears at the end of the propeller shafts were drilled out

to create spokes. This greatly reduced the weight of this heavy

part.

|

Each propeller is screwed to a flange on the trailing end of its

shaft, then drawn tight with a large nut. The threads are cut so the

nut tightens as the prop turns. This prevents the prop from working

loose.

|

Note the homemade turnbuckles on the bracing wires that hold the

prop shafts in alignment. Of all the hundreds of wires on this

aircraft, this is the only place the Wrights thought to adjust the

tension.

|

The Flyer III was the first to have the Wrights' trademark

"bent-end" props. This unique profile kept the props from distorting

and flattening during flight.

|

The Wrights were the first to guess that props were in fact whirling

wings, Consequently, prop blades are curved -- they have a camber

just like aircraft wings.

|

Two long outriggers attached to the rear spars support the rudder.

These outriggers are hinged so that if the rudder strikes the

ground, they pivot upwards.

|

|

(Left) The rudder looks like a large box-kite with two control

surfaces spaced about 18 inches apart. (Above) It rests on the

trailing end of the bottom outrigger.

|

The rudder pivots on the outriggers. As the pilot moves the rudder

control lever in the cockpit right or left, the rudder moves

accordingly.

|

The rudder control surfaces are mounted to a pivot board, positioned

closer to the leading edge than the trailing edge. This arrangement

makes the rudder tend to straighten itself in the air stream.

|

The top of the rudder is similar to the bottom, with a pivot board

holding the rudder surfaces. However, the top pivot comes down from

the top rather than up through the bottom of the board.

|

The framework of the rudder is not glued. Instead, the tension of

the cloth the covers it keeps the wooden pieces together. This metal

tab at the trailing edge keeps the two adjoining pieces in

alignment.

|

The rudder is rigged with diagonal bracing wires like the wings and

the elevator. The Wrights used this same truss system throughout the

airframe because it was both light and strong.

|

A look up the centerline of the Flyer, through the rudder to the

wings and elevator.

|

Here's something you're not likely to see in a visit to Wright Hall

-- the inside of the Wright tool chest. The writing on the inside of

the lid says, "This came for Orville Wright's lab. I.W.M. The

initials stand for Ivonette Wright Miller, Orville's niece.

|

The chest has five sliding drawers inside, arranged so a workman has

access to the entire contents of the chest without having to remove

a drawer. Here the two top drawers are spread apart, revealing one

of the drawers on the middle level.

|

With the two top and the two middle drawers pushed toward the front

of the chest, you can see single deep drawer at the bottom.

|

And here are the two top, two middle, and single bottom drawer all

slid towards the back of the tool chest, revealing a deep "well"

where large tools can be stored.

|

|

Other Voices

|

|

|